Biobased

As a family business, LAPP thinks long-term and acts responsibly. This is why LAPP endeavours to use fewer raw materials, generate less waste and reduce CO2 emissions in the production and distribution of its products. Sustainable product design extends across the entire value chain. The best example: ETHERLINE® FD bioP Cat.5e, the first series cable with bio-based plastic content in the outer sheath. Further lines with a reduced CO2 footprint will follow in the future. LAPP is thus a partner for sustainable development in the industry and helps its customers to pursue their sustainability goals.

What are LAPP's plans for bio-based cables?

The plastics industry is endeavouring to significantly reduce the use of plastics from fossil sources by 2050 (Source: Renewable-carbon.eu). LAPP is also examining approaches to replacing fossil raw materials. This requires experience, a sense of proportion and partners. This is because plastics made from sustainable materials must fully fulfil the product requirements.

LAPP is a pioneer here. The company is currently pursuing two approaches to plastics:

- Plastics made from renewable raw materials such as algae, maize, sugar, rapeseed, sunflower oil or agricultural waste. However, their cultivation must not compete with the production of food and must not destroy the environment.

- Recycled plastics from production waste during a batch change or at the end of production. Here, LAPP is working on promising approaches to utilising these materials as filling, insulation and sheathing materials.

By the way: Copper scrap from production is recycled externally at LAPP and kept in the cycle. LAPP is also a partner of "The Copper Mark", an assurance system for responsible copper production along the entire value chain.

ETHERLINE® FD bioP Cat.5e

The ETHERLINE® FD bioP Cat.5e is the first bio-based cable to be manufactured in series. Its thermoplastic polyurethane (TPU) cover is made from 43 % renewable raw materials. The carbon footprint of this special outer sheath is 24% lower than that of a conventional outer sheath based exclusively on fossil raw materials. In terms of its electrical and mechanical properties, the data cable is in no way inferior to the variant made from fossil raw materials. It is also suitable for continuous-motion use in drag chains with up to 10 million bending cycles. Halogen-free and flame-retardant materials reduce the possible hazards in the event of a fire. The Bio-TPU outer sheath is resistant to mineral oil-based lubricants and is resistant to many chemicals. The dense shielding braid offers the best properties for electromagnetic compatibility (EMC).

ETHERLINE® FD bioP Cat.5e is just the beginning. Further sustainable variants of proven LAPP cables will follow.

What are bioplastics?

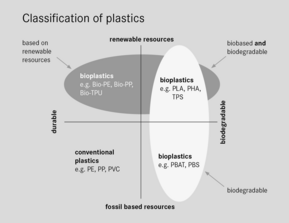

Bio-based plastics are a sustainable alternative to plastics made from fossil raw materials. The raw materials used are wholly or partly of plant origin and can be harvested in a maximum of two growing seasons. Bio-based does not mean that the material is biodegradable - fortunately, because cables must not simply dissolve. However, there are also plastics that are produced from fossil raw materials using chemical processes and are nevertheless (biodegradable). It is important to take a close look here.

How can the carbon footprint shrink?

LAPP reduces its CO2 footprint. This requires many small steps:

Raw materials and products

- Product Carbon Footprint: Complete transparency to reduce the carbon footprint of our products

- Line design: Resource-efficient use of materials and materials from sustainable sources

- Supplier management: High demands on ecological and social sustainability

- Laws: Compliance with restrictions on potentially harmful substances

- Plastics: Growing proportion of materials from sustainable sources

Production and buildings

- Energy supply: More green electricity, also from our own generation

- Energy consumption: Use of energy-saving production systems and optimisation of processes

- Material efficiency: Reuse of materials through internal recycling

Logistics and transport

- Transport routes: Use of rail for almost all transport to and from the seaports (U.I. Lapp GmbH)

- Capacity utilisation: Avoidance of empty runs through optimised route planning

- Packaging: High recycling rate and optimised packaging design

Sustainable with LAPP: What are the benefits for customers?

LAPP has set itself the goal of supporting its customers in achieving their sustainability goals. The basis is high-quality products with a long service life, for example due to their high resistance to oil. Optimising the dimensions of a cable for the respective application is also important. LAPP is also working on the sustainable management of its suppliers. Customers should be able to rely on compliance with the highest ecological and social standards as well as compliance with all legal requirements such as REACH and RoHS. For example, LAPP has lead-free cable glands in its programme. The protection of end users is always in focus, for example with halogen-free cables in rooms where people are present.

LAPP intends to make the emissions data for its products available to its customers in future. Verified product carbon footprints are intended to create transparency about product emissions. The calculation methodology, the data basis and the results will be reviewed by an independent third party in future so that the customer can use this data for its own calculations. LAPP is working to reduce its CO2 emissions at both product and company level.